E-waste Solutions: Companies tackling electronics recycling

Reclaiming Tech’s Hidden Treasure: The Companies Tackling the E-Waste Crisis

In our digital age, electronic devices are the lifeblood of our homes and businesses. Yet, their rapid obsolescence creates a dark byproduct: electronic waste (e-waste). In the UK alone, nearly 30,000 drop-off points exist to recycle old electricals, where 75% of their materials can be reclaimed for new uses—from life-saving medical equipment to children’s playgrounds. This represents a monumental opportunity hidden in plain sight. A growing sector of specialized companies has emerged to meet this challenge, not as mere waste handlers, but as partners in data security, compliance, and building a circular economy.

The E-Waste Imperative: From Problem to Resource

E-waste is one of the fastest-growing waste streams globally. It encompasses everything with a plug, battery, or cable—a category legally defined as Waste Electrical and Electronic Equipment (WEEE). Improper disposal poses significant risks: hazardous substances like lead and mercury can pollute the environment, while lithium-ion batteries pose a serious fire risk if crushed in waste trucks.

The legal framework in the UK, governed by WEEE regulations, mandates that businesses dispose of electronic waste responsibly through licensed facilities. Failure to comply can result in substantial fines and reputational damage. For businesses, the challenge is twofold: ensuring secure data destruction to prevent breaches and guaranteeing environmental compliance.

The Business of Rebuilding Electronics

A new wave of companies is approaching e-waste not as a terminal problem, but as a recovery operation. Their business models are built on extracting maximum value—both economic and environmental—from discarded technology.

Core Business Models in E-Waste Recycling

The Full-Service IT Asset Disposal (ITAD) Partner: Companies like Surplex UK and EGO Technology operate on this model. They provide comprehensive, often free, collection services for businesses, funded by the residual value in the equipment. Their service includes certified data wiping or physical destruction, full environmental processing, and detailed audit trails. EGO Technology reports that over 90% of its services are free due to the rebates generated from refurbishing and reselling viable equipment.

The Secure Destruction & Compliance Specialist: For organizations where data security is paramount—such as government, healthcare, and finance—companies like ZEW and ECS Computer Recycling focus intensely on certified data destruction. They provide military-grade cleansing, on-site shredding options, and guaranteed documentation to meet GDPR and other regulatory requirements.

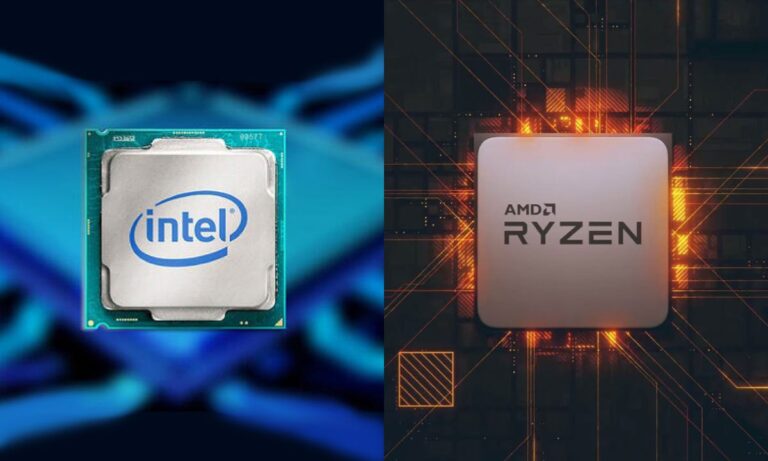

The Advanced Material Recovery Expert: Some firms specialize in the complex chemistry of e-waste. They dismantle devices to the component level to recover precious and critical raw materials. For instance, ZEW lists current market prices for specific components like gold-plated ceramic CPUs (£108/kg) and memory with gold edges (£30/kg), turning specialized recycling into a precise commodity business.

Key Services and Certifications

Reputable companies distinguish themselves through a suite of verified services and credentials. Here is a comparison of key services offered by leading companies:

| Company | Core Service Focus | Key Certifications & Licenses | Unique Value Proposition |

|---|---|---|---|

| Surplex UK | Free ITAD & WEEE Compliance | ISO 14001, EA Licensed, JOSCAR | Free nationwide collection, comprehensive online audit portal. |

| EGO Technology | Corporate IT Disposal & Buy-Back | ISO 9001/14001/27001 | Generates rebates from reuse; provides detailed CO2 saving reports. |

| ZEW | Secure Data Destruction & High-Value Recovery | – | Publishes buy-back prices for components; strong focus on data security. |

| Pure Planet Recycling | Business WEEE Collections & Storage | ISO 14001, Environment Agency Permit | Offers “Wait and Load” collections and on-site storage containers. |

| ECS Computer Recycling | Free IT Collection with Data Destruction | – | Free collection with certified data destruction included as standard. |

The Operational Backbone: Logistics and Processing

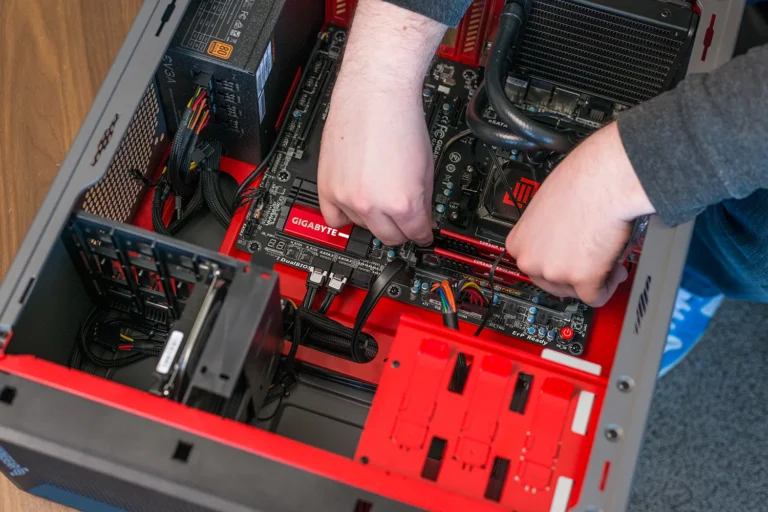

The journey from collection to recovery is a meticulous logistical and technical operation. It begins with secure collection using GPS-tracked vehicles and tamper-proof containers. Companies offer a range of collection solutions, from wheelie bins for small items to roll-on-roll-off skips for large volumes.

At licensed processing facilities, a rigorous sequence follows:

Secure Intake & Auditing: Each item is logged, creating a digital chain of custody.

Data Destruction: Hard drives are either wiped using software that meets standards like the National Cyber Security Centre’s guidelines or physically shredded.

Manual Dismantling: Devices are carefully broken down to separate batteries, screens, circuit boards, plastics, and metals.

Specialized Processing: Components are sent to downstream partners for advanced recovery, such as smelting for metals or specific treatment for hazardous materials like mercury in fluorescent tubes.

Choosing a Responsible Partner

For a business or institution selecting an e-waste recycler, due diligence is critical. Key questions to ask include:

What are your licenses? Ensure they are an upper-tier registered waste carrier with the Environment Agency (or equivalent in Scotland/Wales), which is legally required for transporting other businesses’ waste.

Can you provide full documentation? Insist on a Waste Transfer Note for environmental compliance and a Certificate of Destruction for data-bearing devices.

What is your end-to-end process? Ask where materials go after leaving their facility and what their landfill diversion rate is. True leaders commit to zero-landfill policies.

How do you prioritize reuse? The most sustainable option is always to extend a device’s life through refurbishment. A good partner will have a tested-and-refurbished stream.

Beyond Recycling: The Path to a Circular Tech Economy

The most forward-thinking companies in this space are looking beyond recycling to circularity. This involves designing products for longevity and easy repair from the outset. While recyclers are at the downstream end, their work provides critical feedback on design flaws and material inefficiencies. They are the essential link that recovers the raw materials—cobalt, lithium, gold, copper, rare earth elements—to feed back into manufacturing, reducing the need for virgin mining.

The innovation continues, with research into more efficient separation techniques and higher-purity material recovery. The goal is to close the loop entirely, where an old smartphone doesn’t become waste but the literal building blocks of a new one.

Conclusion

The companies tackling e-waste are proving that responsible end-of-life management for electronics is not a cost center but a strategic, valuable, and essential service. They stand at the intersection of cybersecurity, environmental stewardship, and resource economics. By choosing partners who are transparent, certified, and committed to the highest standards, businesses can transform their liability into a legacy of responsibility, ensuring that today’s technology does not become tomorrow’s toxic burden. In the meticulous work of these recyclers lies the blueprint for a more sustainable relationship with our digital world.

OTHER POSTS